Understanding “Life of Pi” Novel PDF Availability

Finding a digital copy of Yann Martel’s acclaimed novel, “Life of Pi,” often leads to searching for PDF versions online, presenting both convenient access and potential legal complexities.

What is “Life of Pi”?

Yann Martel’s “Life of Pi” is a fantastical adventure novel published in 2001, captivating readers with its compelling narrative and profound philosophical undertones. The story centers around Piscine Molitor Patel, a young Indian boy nicknamed Pi, who survives a shipwreck in the Pacific Ocean. He finds himself adrift on a lifeboat with an unlikely companion: a Bengal tiger named Richard Parker.

The novel is renowned for its magical realism, blending elements of adventure, survival, and spirituality. It explores themes of faith, hope, storytelling, and the human will to live. Pi’s incredible tale raises questions about the nature of reality and the power of narrative to shape our understanding of the world.

Searching for a “Life of Pi” novel PDF often stems from a desire for convenient access to this critically acclaimed work, but it’s crucial to consider the legal and ethical implications of obtaining digital copies.

The Novel’s Core Themes

“Life of Pi” delves into several profound themes, most notably the power of storytelling and its role in constructing reality. The novel presents two versions of Pi’s survival story – one with animals, one with humans – prompting readers to question which narrative is “true” and whether truth itself is subjective.

Faith and spirituality are central, exploring the coexistence of different religious beliefs and the human need for meaning in the face of adversity. Pi’s devotion to multiple faiths highlights the universality of spiritual seeking. Survival, both physical and emotional, is another key theme, showcasing the resilience of the human spirit.

The search for a “Life of Pi” novel PDF can ironically connect to the novel’s themes, as accessing information digitally raises questions about authorship, ownership, and the dissemination of stories in the modern age.

Finding a “Life of Pi” Novel PDF

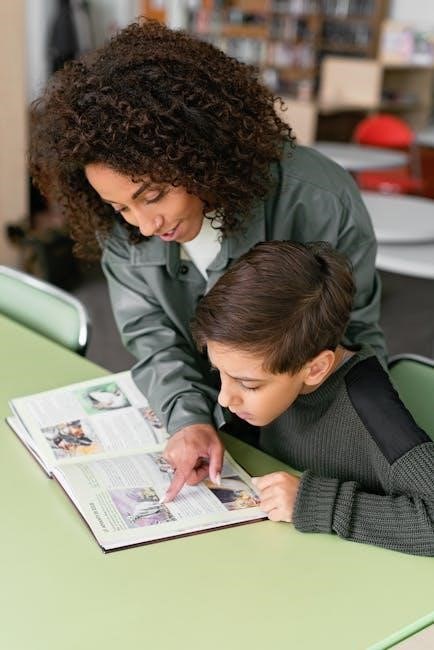

Locating a “Life of Pi” PDF involves exploring online bookstores, digital libraries, and educational resources, but caution regarding copyright is essential.

Legitimate Sources for PDF Downloads

Securing a legal PDF copy of “Life of Pi” requires utilizing authorized platforms. Reputable online bookstores, such as Amazon Kindle Store, Barnes & Noble Nook, and Kobo, frequently offer the novel in PDF format for purchase. Digital lending libraries, like OverDrive and Libby, provide access to ebooks, including “Life of Pi,” through library memberships – a cost-effective and legal avenue.

Furthermore, some educational institutions and universities may grant students access to digital copies via their online learning platforms. Project Gutenberg, while primarily focused on public domain works, is worth checking, though “Life of Pi” is still under copyright. Always verify the source’s legitimacy before downloading to ensure compliance with copyright laws and avoid potential malware risks. Purchasing directly from the publisher or authorized retailers guarantees a safe and legal reading experience.

Free vs. Paid PDF Options

The allure of free “Life of Pi” PDF downloads is strong, but often comes with significant drawbacks. While seemingly appealing, these sources frequently violate copyright laws and may expose users to viruses, malware, or compromised personal data. Paid PDF options, conversely, offer a secure and legal reading experience.

Purchasing from authorized retailers guarantees a high-quality, DRM-protected file, supporting the author and publisher. Free options often present low-resolution scans or poorly formatted text. The cost of a paid PDF is a small price to pay for peace of mind and ethical consumption. Consider digital lending libraries as a ‘free’ legal alternative with a library card. Weighing the risks and benefits clearly favors legitimate, paid sources for accessing “Life of Pi” in PDF format.

Potential Risks of Unofficial PDFs

Downloading “Life of Pi” PDFs from unofficial sources presents a multitude of risks beyond simply violating copyright. These files can harbor malware, viruses, and spyware, compromising your device and personal information. Phishing attempts are also common, disguised as legitimate download links leading to malicious websites.

Furthermore, the quality of these PDFs is often severely compromised, featuring missing pages, distorted formatting, or unreadable scans. You risk encountering incomplete or corrupted files, ruining your reading experience. Supporting these illegal distributions financially incentivizes further copyright infringement. Prioritize your digital security and ethical considerations by opting for authorized, legal avenues to obtain the novel in PDF format, safeguarding yourself from potential harm.

“Life of Pi” Novel: A Detailed Overview

Yann Martel’s “Life of Pi” is a fantastical adventure exploring faith, survival, and storytelling, captivating readers with its unique narrative and profound themes.

Plot Summary: The Journey of Pi Patel

The narrative begins with Pi Patel recounting his childhood in Pondicherry, India, filled with a fascination for zoology and diverse religious beliefs. A pivotal moment arrives when his family decides to emigrate to Canada, selling their zoo and embarking on a sea voyage aboard a Japanese cargo ship, the Tsimtsum.

Tragedy strikes when the ship encounters a violent storm and sinks, leaving Pi as the sole human survivor adrift in a lifeboat. However, he is not entirely alone; he shares his precarious refuge with a Bengal tiger named Richard Parker, an orangutan, a zebra, and a hyena.

The ensuing journey is a harrowing tale of survival, as Pi contends with starvation, thirst, and the constant threat posed by Richard Parker. He learns to coexist with the tiger, establishing a fragile balance of fear and respect. The story details Pi’s ingenious methods for securing food and water, and his desperate attempts to signal for rescue. Ultimately, Pi reaches the shores of Mexico, forever changed by his extraordinary ordeal.

Character Analysis: Pi Patel

Piscine Molitor Patel, or Pi, is a remarkably resilient and adaptable protagonist. His deep curiosity and fervent faith – embracing Hinduism, Christianity, and Islam – demonstrate an open-mindedness and a search for meaning beyond the confines of single belief systems. This spiritual flexibility proves crucial to his survival.

Pi’s intelligence and resourcefulness are evident in his ability to apply his zoological knowledge to understand and manage the animals sharing his lifeboat. He isn’t simply surviving; he’s observing and learning even in the face of unimaginable hardship.

Despite the trauma he endures, Pi maintains a remarkable composure, crafting narratives and routines to cope with his isolation and fear. He’s a storyteller, and his tale, whether literal or metaphorical, reveals a profound need to find order and meaning in chaos. His character embodies the human spirit’s capacity for endurance and the power of belief.

Character Analysis: Richard Parker

Richard Parker, the Bengal tiger, is arguably the most compelling character in “Life of Pi,” despite being an animal. He represents Pi’s primal instincts, his will to survive, and the darker aspects of human nature. Parker isn’t merely a companion; he’s a force that keeps Pi alert and focused on survival.

The tiger’s presence forces Pi to confront his own animalistic side, pushing him beyond his physical and emotional limits. He must learn to respect and fear Parker, establishing a complex, uneasy coexistence. This dynamic is crucial to Pi’s journey.

Parker’s ambiguity – whether he is real or a projection of Pi’s psyche – is central to the novel’s interpretation. He embodies the raw power of nature and the necessity of confronting one’s inner demons. Ultimately, Richard Parker symbolizes the life force within Pi himself, driving him to overcome impossible odds.

Symbolism in “Life of Pi”

“Life of Pi” is richly layered with symbolism, elevating it beyond a simple adventure story. The ocean itself represents the vast, unpredictable nature of life, full of both beauty and terror. The lifeboat symbolizes the fragile vessel of human existence, tossed about by fate’s currents.

Richard Parker, as previously discussed, embodies Pi’s primal instincts and survival mechanisms. The color orange, frequently appearing throughout the novel – in the lifeboat, the tiger, and the sky – symbolizes hope, warmth, and spiritual awakening.

Pi’s stories, both the animal and human versions, symbolize the human need for narrative and meaning-making. The novel suggests that stories, even fantastical ones, can offer profound truths about the human condition and our search for purpose in a chaotic world. Ultimately, the symbolism invites readers to contemplate the nature of reality and belief.

The Narrative Structure: Framing Device

Martel employs a sophisticated framing device, beginning with the author meeting Pi Patel and hearing his incredible story. This initial encounter establishes a layer of questioning – is Pi’s tale true, or a fabrication? The narrative then unfolds as Pi’s first-person account, immersing the reader in his harrowing journey.

The framing returns at the novel’s conclusion, with the author presenting a second, more brutal version of the story involving human characters. This parallel narrative forces the reader to confront the power of storytelling and the subjective nature of truth.

The framing device isn’t merely stylistic; it’s integral to the novel’s themes. It suggests that we construct narratives to cope with trauma and find meaning, and that the “better story” – even if untrue – can be more valuable than a harsh reality. It challenges us to consider why we choose to believe.

Analyzing the Different Interpretations

“Life of Pi” sparks debate, inviting allegorical, psychological, and spiritual readings, prompting discussions about faith, survival, and the human need for compelling narratives.

The Allegorical Interpretation

Many critics and readers view “Life of Pi” as a profound allegory, suggesting Pi’s fantastical journey isn’t a literal recounting of events, but rather a symbolic representation of faith and storytelling itself. The tiger, Richard Parker, often embodies Pi’s primal instincts and the will to survive, a force necessary for enduring hardship.

The entire narrative can be interpreted as a coping mechanism, a more palatable story Pi constructs to deal with the trauma of the shipwreck and the brutal realities he faced. The alternative, darker tale he shares with the Japanese investigators – involving human sacrifices – is seen as the unvarnished truth, while the animal story is a beautiful, albeit fabricated, shield against unbearable pain.

This interpretation emphasizes the power of narrative to shape our understanding of reality and the human need for meaning, even in the face of senseless suffering. The PDF format allows wider access to these interpretations, fostering continued discussion and analysis of Martel’s complex work.

The Psychological Interpretation

A psychological lens reveals “Life of Pi” as a compelling exploration of trauma, dissociation, and the human psyche’s defense mechanisms. Pi’s elaborate story, particularly the presence of Richard Parker, can be viewed as a manifestation of his internal struggles and a way to externalize his fears and anxieties following the shipwreck.

The isolation and extreme conditions Pi endures likely triggered dissociative states, allowing him to create a fantastical reality as a means of psychological survival. Richard Parker, in this context, represents Pi’s darker impulses and the raw instinct for self-preservation, aspects of himself he might otherwise repress.

The availability of the novel in PDF format facilitates academic study, allowing psychologists and literary scholars to dissect the narrative’s intricate portrayal of the human mind under duress. It’s a testament to the enduring power of storytelling to illuminate the complexities of the human condition.

The Religious and Spiritual Aspects

“Life of Pi” profoundly explores faith, belief, and the search for meaning in the face of adversity, incorporating elements from Hinduism, Christianity, and Islam. Pi’s simultaneous practice of multiple religions isn’t presented as contradictory, but rather as a testament to his inclusive spiritual worldview and a desire to connect with the divine through diverse paths.

The novel questions the nature of truth and the power of storytelling as a means of conveying spiritual understanding. The ambiguity surrounding which version of the story is “true” encourages readers to consider the subjective nature of faith and the role of narrative in shaping our beliefs.

Accessing the novel in PDF format allows for focused study of these themes, enabling readers to analyze the symbolic representations of religious imagery and contemplate the deeper philosophical questions raised by Martel’s work. It’s a journey into the heart of human spirituality.

“Life of Pi” and its Adaptations

The novel’s compelling narrative spurred a successful 2012 film adaptation, broadening its reach; PDF versions offer convenient access to the original story.

The 2012 Film Adaptation

Ang Lee’s 2012 film adaptation of “Life of Pi” garnered significant critical acclaim and commercial success, largely due to its stunning visual effects and faithful, yet interpreted, portrayal of Yann Martel’s novel. The film, starring Suraj Sharma as Pi Patel, brought the fantastical journey to life in a way previously only imagined by readers.

Interestingly, the availability of the novel in PDF format surged around the time of the film’s release, likely driven by increased public interest. Many sought to experience the source material before or after viewing the cinematic adaptation. The film’s success also prompted discussions about the differences between the book and the movie, further fueling the desire to access the original text, often through digital means like PDF downloads.

While the film captures the core themes of survival, faith, and storytelling, it inevitably streamlines certain aspects of the novel. Accessing a PDF version allows readers to delve into the nuanced details and philosophical explorations present in Martel’s writing, offering a richer and more complete understanding of Pi’s incredible story.

Differences Between the Book and the Movie

Despite Ang Lee’s admirable effort, the film adaptation of “Life of Pi” inevitably diverges from Yann Martel’s novel in several key aspects. The book delves much deeper into Pi’s philosophical and religious contemplations, offering extended internal monologues absent from the visual medium. Consequently, the search for a “Life of Pi” novel PDF often stems from a desire to experience this richer, more introspective narrative.

Furthermore, the novel’s framing device – the author’s visit with Pi – is more pronounced, adding layers of ambiguity and questioning the veracity of the story. The film streamlines this element. The PDF version allows readers to revisit these crucial narrative layers at their own pace.

Ultimately, while the film provides a visually stunning interpretation, the novel offers a more complex and nuanced exploration of faith, survival, and the power of storytelling. The availability of the PDF facilitates a direct comparison, allowing audiences to appreciate the unique strengths of each medium.

Critical Reception of the Novel

Yann Martel’s “Life of Pi” garnered widespread critical acclaim upon its 2001 publication, winning the Man Booker Prize and becoming an international bestseller. Critics lauded its imaginative storytelling, philosophical depth, and exploration of themes like faith, survival, and the human condition. The novel’s unique narrative structure and compelling protagonist resonated deeply with readers and reviewers alike.

However, some critics found the novel’s ambiguity frustrating, questioning the reliability of Pi’s narrative and the open-ended nature of its interpretation. Despite this, the overwhelmingly positive response fueled demand for the book, contributing to the proliferation of digital copies, including the sought-after “Life of Pi” novel PDF.

The enduring popularity and critical recognition solidify “Life of Pi” as a modern literary classic, prompting continued discussion and analysis, often facilitated by accessible digital formats like PDFs.

Technical Aspects of PDF Files

“Life of Pi” novel PDFs vary in size and quality; compatibility depends on the device, and security features may restrict copying or printing content.

PDF File Size and Quality

The file size of a “Life of Pi” novel PDF is directly correlated with its quality and the method used to create it. PDFs generated from scanned images of the physical book tend to be significantly larger than those created from digital text. This is because image-based PDFs store each page as a series of pixels, while text-based PDFs store the content as actual characters, resulting in a smaller file size.

Quality is also affected by the resolution of scanned images. Higher resolution scans produce clearer text and images but increase the file size. Text-based PDFs offer sharper text, especially when zoomed in, and allow for searchable content. However, formatting can sometimes be lost during conversion from other formats. A well-optimized PDF will balance file size and quality, ensuring readability without being excessively large for storage or download.

Consider that a larger file size doesn’t always equate to better quality; it often indicates a less efficient encoding method. Therefore, assessing both the file size and visual clarity is crucial when choosing a “Life of Pi” PDF.

Compatibility with Different Devices

PDF files, generally, boast excellent cross-platform compatibility, making a “Life of Pi” novel PDF accessible on a wide range of devices. Smartphones (iOS and Android), tablets, laptops, and desktop computers – all can readily open and view PDFs with appropriate software. Most modern operating systems include built-in PDF viewers, such as Apple’s Preview on macOS and Microsoft Edge on Windows.

However, compatibility can vary slightly depending on the PDF’s features. PDFs with complex formatting, interactive elements, or embedded fonts might display inconsistently on older devices or less common operating systems. Ensuring the PDF adheres to standard PDF specifications maximizes compatibility.

For optimal reading experience, dedicated PDF reader applications like Adobe Acrobat Reader, Foxit Reader, or others offer advanced features like zoom, search, and annotation. Cloud storage services also provide convenient access to PDFs across multiple devices, ensuring you can enjoy “Life of Pi” wherever you are.

PDF Security Features

PDF files offer several security features that can protect a “Life of Pi” novel PDF from unauthorized access or modification. These features range from basic password protection to more advanced digital signatures and encryption. Password protection restricts access to the file, requiring a user to enter a password to view or print the content.

Digital signatures verify the authenticity of the PDF and ensure it hasn’t been tampered with since it was signed. Encryption scrambles the file’s content, making it unreadable without the correct decryption key. However, the effectiveness of these security features depends on their implementation.

Unofficial PDFs downloaded from untrusted sources may lack these security features or even contain malicious code. Always verify the source and scan the file with antivirus software before opening it. Legitimate sources typically employ robust security measures to protect their digital content, ensuring a safe reading experience.

Legal Considerations Regarding PDFs

Downloading and distributing copyrighted “Life of Pi” PDFs without permission violates copyright law, raising ethical concerns about respecting authorial rights and intellectual property.

Copyright Laws and Digital Content

Copyright law protects original works of authorship, including novels like Yann Martel’s “Life of Pi.” This protection grants the copyright holder – typically the author and publisher – exclusive rights to reproduce, distribute, and adapt the work. Downloading a PDF of “Life of Pi” from unauthorized sources constitutes copyright infringement, a legal violation with potential consequences.

Digital content, despite its intangible nature, is subject to the same copyright protections as physical books. The Berne Convention and the Digital Millennium Copyright Act (DMCA) are international and US laws, respectively, that reinforce these rights in the digital realm. Sharing a copyrighted PDF, even without profit, can be considered infringement.

Legally obtaining a “Life of Pi” PDF requires purchasing it from authorized retailers or accessing it through legitimate subscription services. Understanding and respecting copyright laws is crucial for supporting authors and fostering a sustainable literary ecosystem. Violating these laws can lead to fines and legal action.

Ethical Considerations of Downloading PDFs

Beyond the legal ramifications, downloading a “Life of Pi” PDF from unofficial sources raises significant ethical concerns. Authors rely on book sales and royalties to sustain their careers and continue creating impactful works. Unauthorized downloads directly undermine this system, devaluing their intellectual property and effort.

Supporting authors demonstrates respect for their creativity and encourages further literary contributions. Choosing legitimate avenues for accessing the novel – purchasing a physical copy, an ebook, or utilizing library resources – ensures they receive fair compensation.

The availability of free, pirated PDFs often comes at the cost of quality and security, potentially exposing users to malware or viruses. Furthermore, it contributes to a culture of disrespect for intellectual property rights. Ethical consumption promotes a thriving literary community and acknowledges the value of artistic creation.